Ball valves of BVT series of all lines are classified as “Pressure accessories” in the sense of the PED Directive 2014/68/EU, Article 2, paragraph 5. The intended use refrigerants vary according to the specific line, also determining the hazard class in accordance with PED Directive 2014/68/EU.

In accordance with Directive 2014/68/EU, the hazard classification of the product depends on:

• Type of fluid intended for use;

• Intrinsic dimensions (DN, in this case);

• Maximum design working pressure (PS);

The entire line is suitable for use with fluids classified in Article 13, paragraph 1, letter (b), of Directive PED 2014/68/EU as part of Group 2, therefore not toxic, not inflammable, and not explosive fluid; most of these fluids are indicated in Annex E of standard EN 378-1 as Class A1:

• HFC: R134a, R404A, R407C, R410A, R507;

• Blends HFC/HFO: R448A, R449A, R450A, R452A, R513A;

In accordance with Table 7 of Annex II of Directive 2014/68/EU, some products are classified as Category I and must bear the CE mark of European Conformity, some fall in the scope of the Article 4.3 and must not bear the CE mark also if they comply with the Directive itself.

All products also comply with the STATUTORY INSTRUMENTS 2016 No. 1105 – The Pressure Equipment (Safety) Regulations 2016, revised by Product Safety and Metrology etc (Amendment etc.) (EU Exit) Regulations 2019; according to its classification, some products are classified as Category I and bear the UKCA mark which proves their design is in accordance with the cited regulations, some fall in the scope of Regulation 8 and must not bear the UKCA also if they comply with the Regulations themselves.

For use with fluids other than those explicitly indicated, please contact GMC® Refrigerazione.

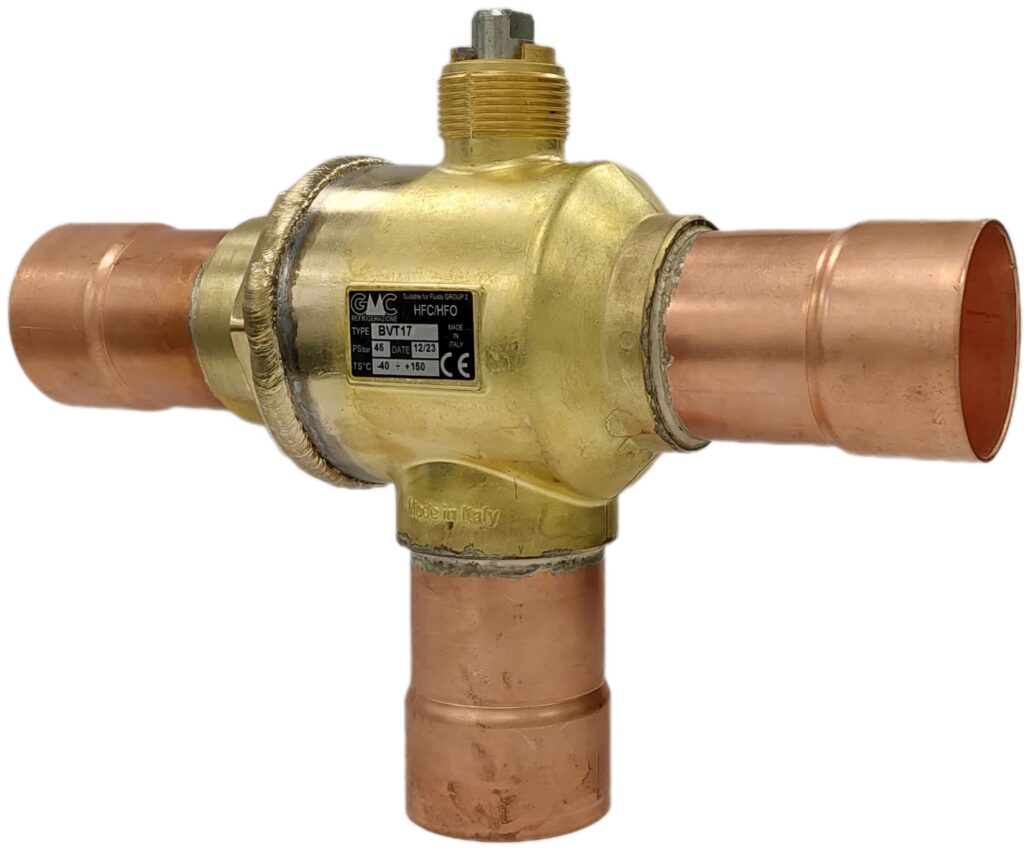

The Three-way Ball Valves (BVT) have the body and the sleeve made of hot forged brass UNI EN 12420 – CW617N, while the relative connections are made of copper tube EN 12735-1 – CuDHP; the spindle, designed to completely avoid the danger of expulsion, is made of treated steel, while the relative pin is made of stainless steel. The body and the sleeve are assembled using a threaded connection, therefore welded; the HNBR sealing rings placed on the operating spindle ensure the perfect hermetic seal of the tap towards the outside.

The sealing gaskets on the ball, in special modified PTFE, guarantee low operating torques and the total absence of seat leakage up to pressure differentials much higher than the PS of design. The cap, if tightened with the right torque, guarantees the absolute isolation of the product against the external enviroment; on request, it’s possible to also order the BVT with a brass cap.

The three-way ball valve connects the lower connection with one of the two upper ones, depending on how the sphere is maneuvered. The design of the valve is such as to allow the bidirectionality of the flow, and the mounting position can be any, according to the needs; for motorized is suggested a mounting position that keeps vertical the axis of the maneuvering spindle. The whole series is designed for motorization with Belimo® actuators through the use of a special connection flange (AMBV).

For more detailed information, please check the subsection “Motorized ball valve (BV, BVT) on our catalog.